BLDC Motor Controller (BLMD-2406)

Product Description

The specification of high performance controller

BLMD2406 controller uses dedicated high-performance Brushless DC Motor IC from USA. This controller is suitable for driving brushless dc motors with small and medium power. The motor operates with high speed, small vibration, low noise and stable running due to the new PWM technology

1. Characteristic

2. Pin description

3. Electrical Characteristics (Tj=25ºC)

4. Using environment and parameters

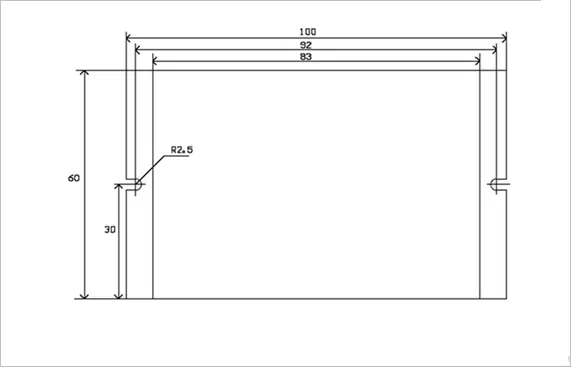

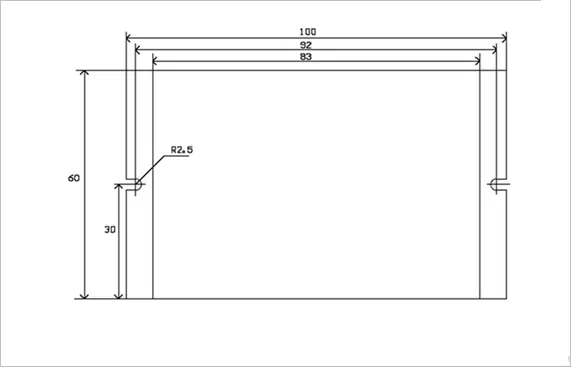

5. Mechanical installation

Chart 1: Mechanical Dimensions

6. Power supply

Normal operating voltage is from 20V to 36V. The driver can be supplied by unregulated DC power. Step-down transformer + bridge rectifier + capacitor filter also. Capacitance can greater than 2200μF. But care should be taken that the rectified voltage ripple peak value is no more than 20V.If you use regulated switching power , note that the output current range of switching power need to be larger than 10A.

Please note: 1.Best to use non-regulated power

2.When using non-regulated power , the output capacity of power current should be higher than 60% current of controller. When using power, the output capacity should be higher than current of controller.

3. In order to reduce the cost, 2 or 3 controllercan share the power. But should improvethe rated power &rated output current of power and pay attention to the heat.

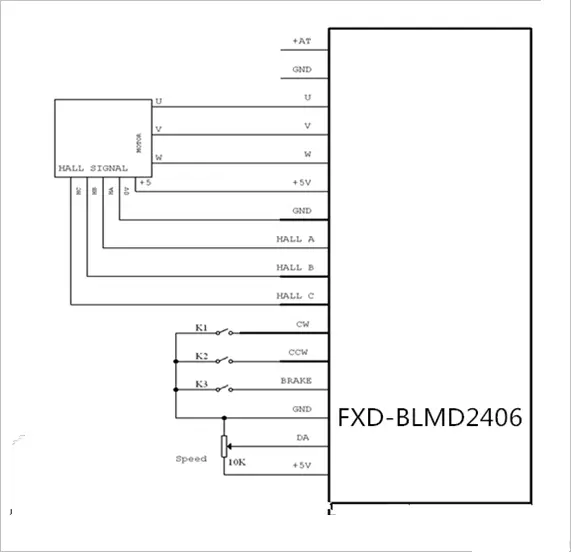

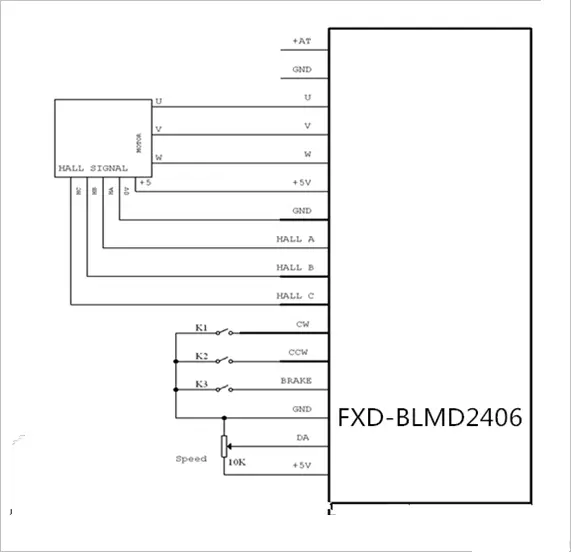

7. Driver Wiring

A complete brushless DC Motor control system should contain a brushless Dc Motor, brushless DC motor controller, DC power and control signals. The following is a typical system diagram

8. Fault Phenomenon and Ruled Out

When the power is on, the emitting tube is with 1-second light and 1-second dark. CW terminal or CCW terminal is with low level. The emitting tube light for long time when the driver operates.

Default phase: emitting tube flare for 2 times and dark for long time-- Check the Hall signal

Restricted rotation or over current: emitting tube flare for 3 times and dark for long time-- Check the Hall signal & Check whether the dead load & Check whether motor with short circuit

BLMD2406 controller uses dedicated high-performance Brushless DC Motor IC from USA. This controller is suitable for driving brushless dc motors with small and medium power. The motor operates with high speed, small vibration, low noise and stable running due to the new PWM technology

1. Characteristic

| 1 | DC voltage | 20VDC-36VDC |

| 2 | PWM frequency | No less than 12KHZ |

| 3 | The input signal is compatible with TTL | |

| 4 | Drive current | Up to 8A |

| 5 | Open loop &closed loop speed control | General Settings for the open loop before delivery, Users can request to set the maximum closed loop speed. Users can own change the maximum closed loop speed. The change of closed loop speed should be operated by professionals. |

| 6 | Dimensions | 85 * 59 * 19 |

| 7 | Weight | 0.11Kg |

2. Pin description

| 1 | +ATG,ND terminal | External DC power |

| 2 | U terminal | Motor phase U |

| 3 | V terminal | Motor phase V |

| 4 | W terminal | Motor phase w |

| 5 | + 5V terminal | Hall element power |

| 6 | GND terminal | Hall element power negative terminal namely 0V |

| 7 | HALL A | Hall element phase A |

| 8 | HALL B | Hall element phase B |

| 9 | HALL C | Hall element phase C |

| 10 | CW terminal | Motor's enable terminal for forward run, effective with low level |

| 11 | CCW terminal | Motor's enable terminal for reverse run, effective with low level |

| 12 | BRAKE terminal | Brake inputs terminal, effective with low level |

| 13 | DA terminal | Speed control terminal, usually 0-5V |

| 14 | ACC potentiometer in the driver | Control acceleration and deceleration time, within 0.1s and 5s |

3. Electrical Characteristics (Tj=25ºC)

| 1 | DC voltage | 20VDC to 36VDC |

| 2 | Maximum output current | 8A |

| 3 | Insulation resistance | Higher than 500MΩ |

4. Using environment and parameters

| 1 | Cooling | Natural cooling or forced air cooling |

| 2 | Environment | No dust and corrosive gases |

| 3 | Temperature | 0 ° C- + 50 ° C |

| 4 | Humidity | 40- 89% RH |

5. Mechanical installation

Chart 1: Mechanical Dimensions

6. Power supply

Normal operating voltage is from 20V to 36V. The driver can be supplied by unregulated DC power. Step-down transformer + bridge rectifier + capacitor filter also. Capacitance can greater than 2200μF. But care should be taken that the rectified voltage ripple peak value is no more than 20V.If you use regulated switching power , note that the output current range of switching power need to be larger than 10A.

Please note: 1.Best to use non-regulated power

2.When using non-regulated power , the output capacity of power current should be higher than 60% current of controller. When using power, the output capacity should be higher than current of controller.

3. In order to reduce the cost, 2 or 3 controllercan share the power. But should improvethe rated power &rated output current of power and pay attention to the heat.

7. Driver Wiring

A complete brushless DC Motor control system should contain a brushless Dc Motor, brushless DC motor controller, DC power and control signals. The following is a typical system diagram

Chart 2 Drive wiring diagram

8. Fault Phenomenon and Ruled Out

When the power is on, the emitting tube is with 1-second light and 1-second dark. CW terminal or CCW terminal is with low level. The emitting tube light for long time when the driver operates.

Default phase: emitting tube flare for 2 times and dark for long time-- Check the Hall signal

Restricted rotation or over current: emitting tube flare for 3 times and dark for long time-- Check the Hall signal & Check whether the dead load & Check whether motor with short circuit

Product Categories : Brushless DC Motor Driver

Premium Related Products

Other Products

Hot Products

90w 220V bldc electric motor with gearbox and controller60w single phase low rpm electeic ac induction motor40w low rpm small electric ac reversible gear motor with gearboxsingle phase three phase 100v 110v 120v 220v 230v ac magnetic brake motor15w single phase low rpm ac small gear speed control motor36v 500w Single Axel Motor Wheel Electric For High speed scooter DIY12 inch Gear Hub Motor For Tricycle Design For Old disable People120w Micro Low Voltage 48V DC Brushless Motor Speed Control/ Driver30W 24V DC Brushless Transmission Planetary Gear Motor with driverNEMA23 closed loop motor kit 2 phase hybrid easy servo stepper motor kitHeight Adjustable Sit Stand Up Office Standing Desk lifting columns6000N Disabled vehicles adjust dc 24v linear actuator2000N 28mm/s Electric automatic linear actuator for Fruit bin shuttle lift12v/24v 120W positive and negative deceleration speed worm gear motor90W high torque low speed 110v brushless dc motorHigh Voltage Brushless Asynchronous 8000 rpm Servo Motor 30KW